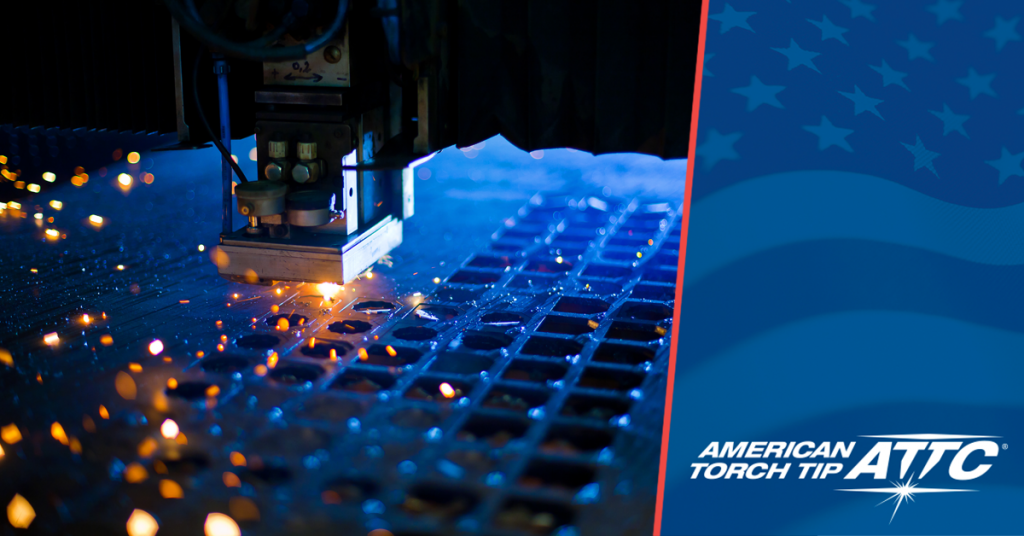

You’ve likely heard that fiber lasers are the new CO2 lasers. But is fiber really that much better, or is it just clever marketing? Here’s a look at the differences between CO2 and fiber laser cutters, and why it might be time for you to upgrade to fiber laser.

CO2 laser cutting machines have been in use for more than five decades, and they were considered the standard for most of those years. But, when fiber laser cutters entered the game, they quickly overshadowed their CO2 counterparts. Today, they account for around 80% of the market for ¼-inch sheet metal including steel, stainless steel, and aluminum.

What’s the Fuss About Fiber?

Why have manufacturers been so quick to make the switch? While CO2 laser cutters still show superior performance in some areas, particularly thicker pieces over ½ inch, the potential savings in switching from CO2 to fiber laser cutters can be significant.

Maintenance

CO2 and fiber laser cutters are nearly opposite in their operation and maintenance. CO2 cutters work by focusing a laser beam onto the material via a series of mirrors and other complicated optics. It’s a precision machine that requires nearly constant maintenance and an expert to fix misalignment issues.

RELATED: CO2 Laser Cutting vs. Fiber Laser Cutting: Pros and Cons

On the other hand, fiber cutters deliver the laser beam via a bank of diodes and a fiber-optic cable, which means there are no moving parts to maintain. Although it also requires maintenance, this type of cutter is far more self-sufficient, and almost cut-ready right out of the box. So, compared to CO2 cutters, there is significantly less ongoing maintenance needed for fiber lasers.

Power

Many of fiber laser’s other advantages come from the design of not only the cutting machine, but the power and focus of the laser beam itself. Because of its shorter wavelength and more concentrated focal point, a fiber laser beam can generate a power density up to five times higher than a comparable CO2 laser — this translates into higher feed rates than CO2 alone.

A fiber laser cutter is also more electrically efficient in a number of areas, including light generation and power consumption. Combined with the higher speeds and less maintenance, it can lead to operating costs that are up to 50% lower than CO2.

Gas

Both CO2 and fiber laser cutting machines use an auxiliary gas, commonly nitrogen, oxygen or air, to remove the slag from the kerf. But as its name suggests, the CO2 laser beam is also formed by a combination of ultra-high purity gases which are excited by radio frequent or direct current.. This additional gas system adds significant cost to the overall operational cost, as well as the need for specific regulators and plumbing.

RELATED: Gas gives the big assist in laser cutting

Productivity

The combination of faster cutting speeds, less downtime and half the operating costs of CO2 can lead to long-term savings that well offset the machine’s initial investment. Its shorter wavelength also means 2 ½ times more absorbency, which means it can cut copper, aluminum, brass and other reflective metals without damaging the machine. In addition, fiber lasers have greater versatility, with applications across industries including automotive, mechanical, electrical and even advertising.

Your Experts on Fiber Laser and CO2 Cutting Machines

It can be easy to get stuck in the routine of using outdated equipment. CO2 cutters may seem dependable, but their maintenance and operating costs will end up setting you back more than you know. That’s why fiber lasers are a great alternative, and they will help you stay more productive in the long run.

As experts in cutting and and welding equipment, we are always happy to share information that will benefit others. Keep up with our blog for more industry insights!

Sign up for our Monthly Newsletter

Join our community of over 20,000 industry experts and subscribe to our newsletters to receive product announcements and offers.