Arc welding processes are as varied as the workpieces they create, and choosing the right one is vital to your project’s success. While MIG and TIG welding both form the weld using an electric arc, the techniques are quite different. Choosing the wrong one can lead to more than a headache, it could lead to wasted time, resources, and money.

That’s why it is important to distinguish the appropriate application for a MIG welder or TIG welder. Read on for the reasons you may want to choose MIG welding vs. TIG welding.

(Click here to learn why TIG is better than MIG.)

MIG vs TIG Welding

MIG and TIG welding both use an electric arc to create the weld. The difference between the two is the way the arc is used.

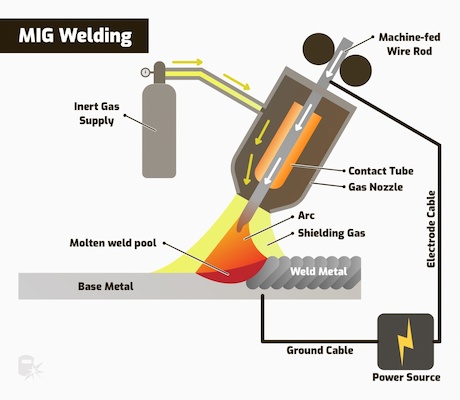

MIG (metal inert gas) welding uses a feed wire that constantly moves through the gun to create the spark, then melts to form the weld. It uses a semi-automatic or automatic arc.

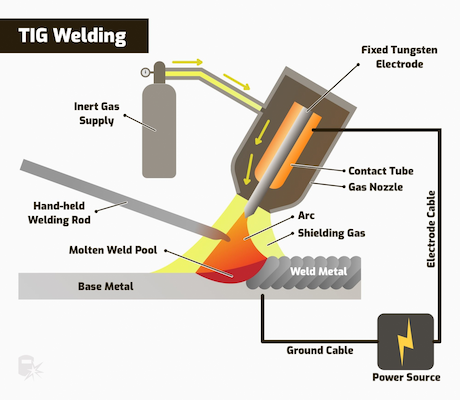

TIG (tungsten inert gas) welding uses long rods to fuse two metals directly together. It uses a non-consumable electrode and a different filler material.

RELATED: Most Common Welding Equipment and Processes

Why MIG Welders Are More Efficient

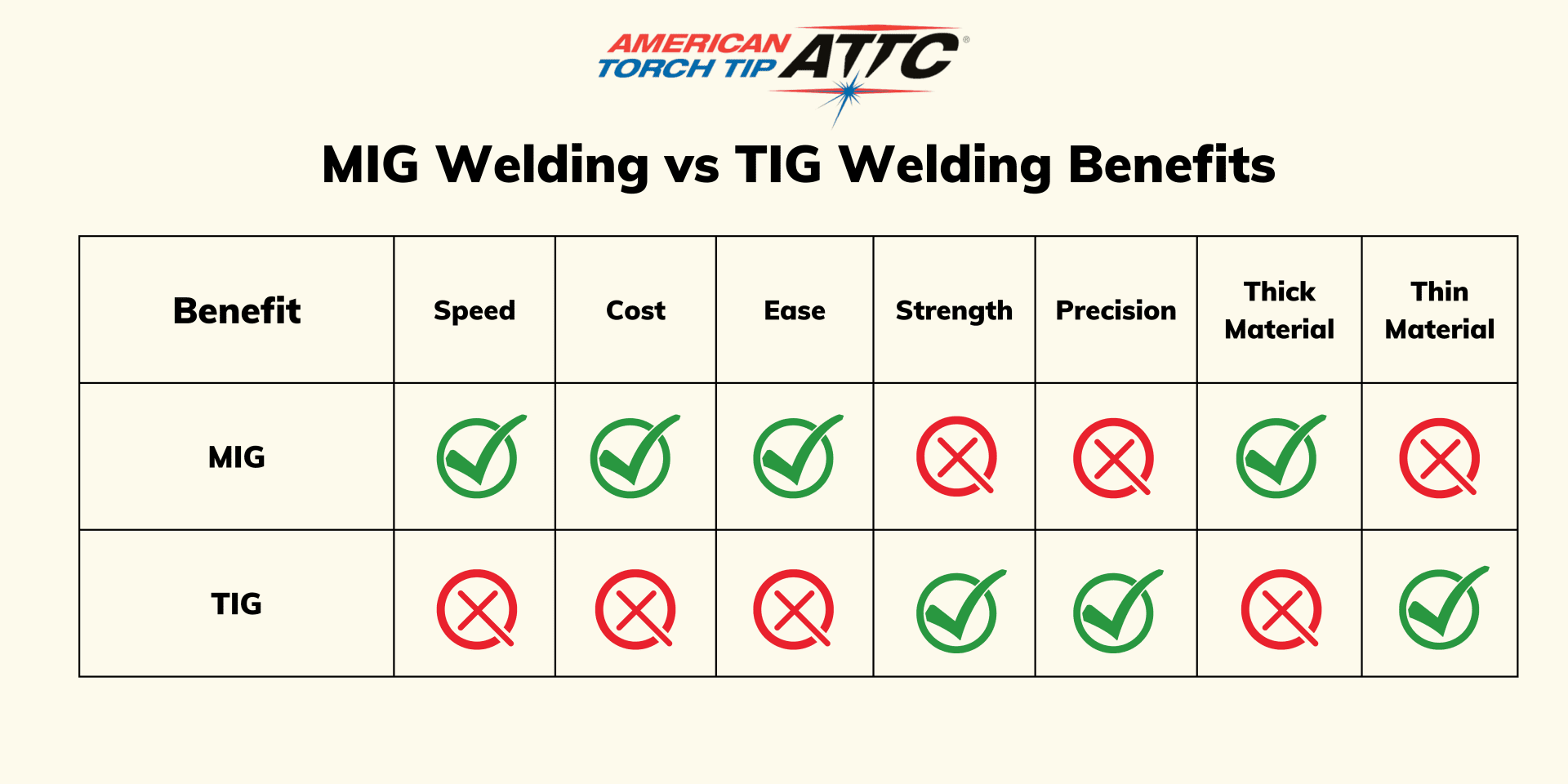

While TIG welding guns have their benefits, there are a number of reasons why MIG welders are more efficient. For our more visual learners, here is a comparison chart of the MIG vs TIG benefits.

Now, let’s explore some of the key benefits of MIG welding in more detail.

Versatility

First, a MIG welder is more diverse. While TIG welding can be used on more types of metals, it’s limited in its effectiveness on thicker jobs. MIG welding can be used on aluminum, stainless steel, and steel, and on every thickness from 26-gauge sheet metal to heavy-duty structural plates. This makes it a popular choice in many industries such as automotive, construction, and manufacturing. The process is also adaptable to different welding positions, such as flat, horizontal, vertical, and overhead, which makes it versatile for various welding applications.

MIG welding holds this advantage over TIG because the wire feed acts not only as an electrode, but also as a filler. As a result, thicker pieces can be fused together without having to heat them all the way through. And because it uses filler rather than fusing, MIG welding can be used to weld two different materials together.

Speed

Another reason for choosing MIG vs. TIG is speed. A MIG gun is designed to run continuously for long periods of time, making them more efficient and productive than its counterpart. MIG welders are efficient is because the process is automated and relatively easy to learn, which reduces the amount of time and effort required for training.

For large, industrial operations that require high production rates, MIG is the go-to choice. The speed of MIG welding also translates into lower labor costs, as welders can complete more welds in a given amount of time. In contrast, TIG welding is a much slower process that’s focused on detail.

Cost

As with any manufacturing job, time equals money. And because the MIG welding process is so much faster, it’s also more cost-effective. MIG parts are also more readily available and far less expensive than TIG.

Moreover, MIG welding machines are typically less expensive than TIG welding machines, and the wire used in MIG welding is less expensive than the tungsten electrode used in TIG welding. MIG welding also uses a consumable wire electrode, which means that there is no need for frequent electrode replacements as there is in TIG welding.

Another factor that makes a MIG welder more cost-effective than TIG welding is the fact that it produces less waste. MIG welding creates less scrap material and less rework than TIG welding, which means that less material is wasted and the overall cost of production is reduced. TIG welding has a lower deposition rate making it more expensive per foot of bead. The initial costs are also a little more than MIG because the consumables are a bit pricier.

Ease

Finally, a MIG welder is easier to learn and can be perfected after just a few weeks of training. In fact, it’s even been referred to as the “hot glue gun” of welding — just pull the trigger to start or stop the weld. A MIG welder can hold and operate the gun with only one hand, making it a better option for beginning welders. TIG welding, on the other hand, is a specialized technique that requires the use of both hands and one foot — all doing separate things.

MIG welding is also easier than TIG welding because it requires less preparation and clean-up time. A MIG welder does not require the use of a tungsten electrode, which must be sharpened and cleaned before use. It also doesn’t require the use of filler rods, which must be cut to the proper length and diameter. MIG welding produces less spatter and requires less post-weld clean-up than TIG welding.

Moreover, MIG welding is easier to learn and master than TIG welding. It can be learned in a relatively short period of time, and welders can become proficient in the process with minimal training. On the other hand, TIG welding requires more time and practice to develop the necessary skills and experience.

RELATED: How to start a career in welding

When to Use MIG Welding

Both TIG and MIG welding have their pros and cons, so it is important that you consider the application. Manufacturers find MIG welding useful when high production is necessary and delicate work isn’t required. It can also be helpful when there aren’t experienced welders available.

Here are applications best suited for MIG welders:

- Thicker materials

- Long runs

- Difficult positioning

Welding Thick Materials

When it comes to thicker materials, MIG welding’s high deposition rates and efficient heat transfer make it an excellent choice. The continuous wire electrode used in MIG welding allows for faster welding speeds, enabling efficient and effective fusion of thicker metal sections.

Additionally, the adjustability of MIG welding parameters, such as voltage and wire feed speed, allows welders to tailor the process to accommodate the specific requirements of thicker materials.

Long Runs

MIG welding is also advantageous for long runs, which involve welding over extended distances without interruptions. The continuous wire feed in MIG welding ensures a constant heat source, making it suitable for continuous welding applications. This eliminates the need to frequently stop and start, resulting in faster and more efficient welding for long runs.

Difficult Positioning

MIG welding can handle difficult positioning scenarios more easily compared to other welding processes. The wire electrode and the use of shielding gases help to protect the weld pool from external factors like drafts, ensuring better arc stability and shielding.

This feature is particularly useful when working in challenging positions, such as overhead or vertical welding, where maintaining proper shielding and controlling the weld pool can be more challenging.

Get High-Quality MIG Welding Parts, Torches, & Guns

Are you a MIG welder looking for high-quality MIG welding equipment? American Torch Tip offers durable MIG welding parts, torches, and guns that are specifically manufactured for welders like you.

Our line of Lightning® MIG guns and consumables are impact resistant, ink-resistant, and ergonomic. With our indestructible handles and swivel-neck technology, welders can get more done with less downtime.

For help with your MIG setup, download our free MIG Ultimate Troubleshooting Guide.

Sign up for our Monthly Newsletter

Join our community of over 20,000 industry experts and subscribe to our newsletters to receive product announcements and offers.