Fill out the form on this page and we'll work with you to demonstrate in-person just how Lightning® can help your business:

- CleanCut™'s ability to reduce the usage of your consumables by 25-30%.

- How CleanCut™ can help you get cleaner cuts with a 2º unintended bevel.

- That CleanCut™ will help you save costs in labor and keep production moving.

Our highly-motivated sales team will follow up within 24 hours of your submission. We'll go more in depth with you on the type of equipment you have and the comparitive differences you should expect to see. We know CleanCut™ will help bring your business to the next level.

DESIGNED AS AN UPGRADE AND COMPATIBLE FOR HIGH-AMPERAGE SYSTEMS SUCH AS:

- ATTC® PHD®, PHDX® 130, 260 & 400 AMP systems

- Hypertherm® HPR® 130, 260 & 400 AMP systems

- Hypertherm® Maxpro-200® systems

- ESAB® PT36®, PT19, & PT600® systems

THE PROCESS

THE TECHNOLOGY BEHIND THE CLEANCUT™ NOZZLE

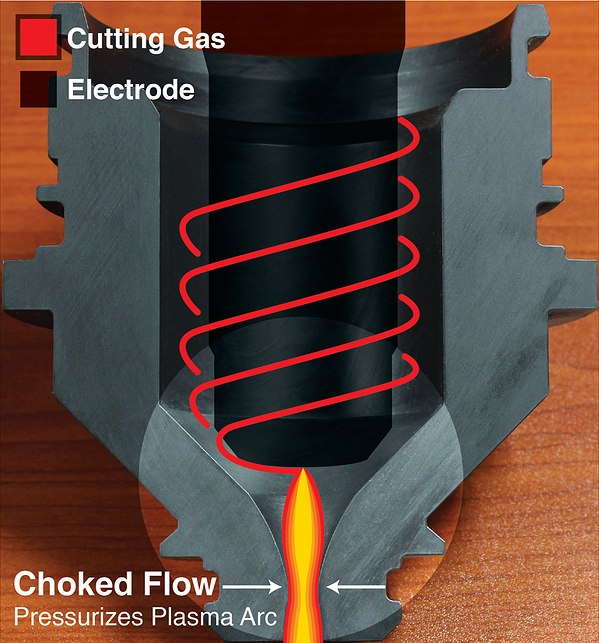

CleanCut™’s high-velocity design reduces turbulence, stabilizes and accelerates the plasma arc column. The design is based on advanced rocket-engine technology and creates smooth cuts.

Compared to standard and high definition designs, CleanCut™'s internal nozzle design pressurises the flow of gas. Once the pressure is released, it provides a more narrow, stable plasma arc. This also allows for a quicker piercing time for thicker plates/materials.

THE TECHNOLOGY BEHIND THE CLEANCUT™ ELECTRODE

CleanCut™ Electrodes are tipped with silver, which helps the plasma consumables run cooler since silver electrodes have a higher thermal-conductivity than copper electrodes. On average, silver electrodes last 2x longer than copper, which increases the life of the rest of your plasma consumables.